Parts

Schrader Valves: Characteristics and Features

Schrader valves, often synonymous with automotive and bicycle applications, have etched a permanent mark in the world of valves. With their unique design and mechanism, they’ve been an indispensable component in many sectors. This article Hookbike’s delves deep into the characteristics and features of Schrader valves, illustrating why they are preferred and how they have evolved to meet contemporary demands.

What are Schrader Valves?

Schrader valves are a type of pneumatic tire valve used on virtually all motor vehicles, including cars, motorcycles, bicycles, and even some industrial applications. Named after its inventor, August Schrader, the valve design was patented in the 1890s. Here are some key characteristics and features of Schrader valves:

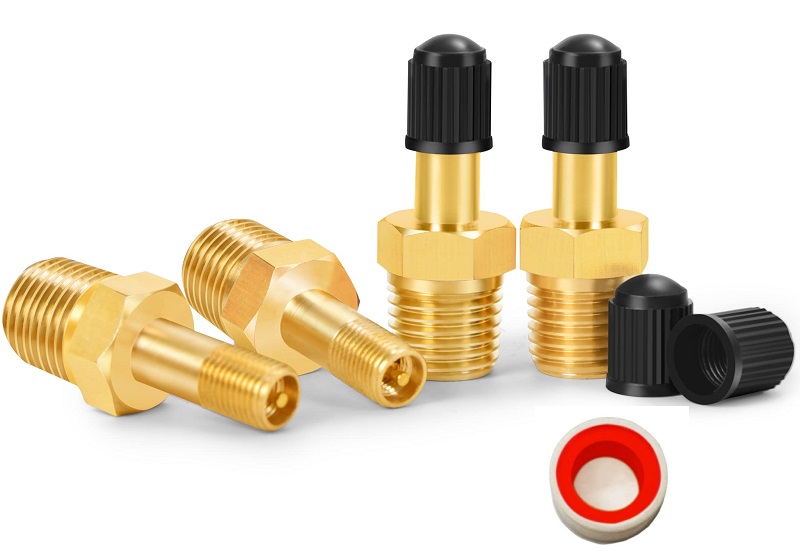

Design: The Schrader valve consists of a cylindrical metal tube with threading on the outside to allow it to be screwed into a threaded hole on the rim. Inside this tube is a metal pin surrounded by a rubber seal. When the pin is depressed, air can flow in or out of the tire or inner tube. When the pin is released, the rubber seal prevents air from escaping.

Functionality: To inflate or check the pressure of a tire, a pump or pressure gauge is attached to the valve, depressing the pin and allowing air to flow in or out. Once the pump or gauge is removed, the pin returns to its original position, sealing the valve.

Protection: A plastic or metal cap usually covers the Schrader valve. While the valve’s internal mechanism prevents air from escaping, this cap provides additional protection from dirt, debris, and moisture.

Comparison with Presta Valves: Bicycles may use another kind of valve called a Presta valve. Presta valves are narrower and are typically found on high-end road and mountain bikes. They don’t have a check pin like Schrader valves; instead, they have a lock nut that needs to be loosened before inflation and tightened afterward.

Applications: While Schrader valves are most commonly associated with automotive and bicycle tires, they are also found in HVAC systems and other industrial applications where pressurized air or gas systems are used.

See more: types of bicycle tire valves

The Schrader valve is a tried-and-true design that’s been in use for well over a century, providing reliable performance in a variety of applications.

Historical Evolution of Schrader Valves

The Schrader valve has an interesting historical evolution, rooted in the broader context of the rapid technological advances of the late 19th and early 20th centuries, particularly in transportation and industry. Here’s a brief overview of the historical evolution of the Schrader valve:

Origins (Late 19th Century): The Schrader valve was invented by August Schrader, a German immigrant to the U.S., in the 1890s. Schrader had initially started a business in New York City in the 1840s, where he manufactured rubber and metal fittings.

Initial Design: The first Schrader valve was developed as a valve for rubber diving suits. Schrader recognized the potential for a reliable, self-sealing valve, and after some design iterations, he applied the concept to pneumatic tires, which were becoming more widespread with the growth of the bicycle and automotive industries.

Patent and Commercial Success: August Schrader and his son George patented the Schrader valve in the 1890s. The reliability and simplicity of their valve design made it an instant commercial success. The growth of the automotive industry in the early 20th century provided a significant market for Schrader valves, as they became the standard for car tires.

Expansion Beyond Tires: As the design proved reliable, the Schrader valve found applications beyond tires. For instance, it became a standard in various industrial applications, especially in pressurized systems like HVAC.

Competition and Standardization: In the bicycle industry, the Schrader valve faced competition, especially from the Presta valve in Europe. However, its broader applicability and ease of use ensured it remained the standard for many types of tires, especially in the automotive industry.

Modern Developments: In recent years, as technology has evolved, there have been modifications to the original Schrader design to cater to specific needs. For instance, there are Schrader valves with integrated pressure sensors for tire pressure monitoring systems (TPMS) in modern vehicles.

Legacy: The Schrader valve’s lasting legacy is evident in its continued widespread use, over a century after its invention. The Schrader Company, founded by August Schrader, is still operational and remains a major player in the industry, producing a variety of valves and related products.

The Schrader valve’s evolution is a testament to its robust and functional design, which has met the demands of various industries for more than a century. It stands as an example of how a simple yet effective invention can have a lasting impact on technology and industry.

Distinctive Characteristics of Schrader Valves

Schrader valves are ubiquitous in various industries, particularly automotive and cycling. Their design has several distinctive characteristics that differentiate them from other valve types:

Dependable Sealing Mechanism

The primary strength of the Schrader valve lies in its core design: the pin, which is central to its sealing mechanism. The valve pin’s depression permits the flow of air, while its release ensures a tight seal, preventing any leaks. This dual functionality ensures that the Schrader valve remains effective and reliable over prolonged usage.

Versatility in Application

Schrader valves are not limited to just automotive or bicycle tires. Their application spans across refrigeration systems, hydraulic systems, and even aircraft. The robust nature of these valves allows them to function seamlessly in varying environments and pressures.

See more: Dunlop Woods Valves

Easy Maintenance and Replacement

One of the attractive characteristics of Schrader valves is their simplicity in design, which translates to ease of maintenance and replacement. Without necessitating the removal of the entire valve, specific components can be changed, ensuring longevity and reducing maintenance costs.

The distinctive characteristics of Schrader valves revolve around their reliable, self-sealing design, their uniformity and versatility across applications, and their adaptability to modern technological integrations.

Key Features Setting Schrader Valves Apart

Schrader valves have several key features that set them apart from other types of valves. To succinctly capture the essence of what makes the Schrader valve distinct:

Durability

Made primarily of brass, Schrader valves boast a high resistance to rust and wear, ensuring they last longer than many alternative valve types. This resilience to environmental factors means that they provide consistent performance across various conditions.

Self-Sealing Design

One of the innovations that make the Schrader valve a favorite is its self-sealing capability. The valve’s internal components are so crafted that upon the removal of an inflation connector, it automatically seals itself, mitigating the risks of rapid depressurization or leaks.

Compatibility with Standard Equipment

Another feature to highlight is the Schrader valve’s compatibility with standard equipment. Given their wide-ranging application, they are designed to work seamlessly with common inflation tools, making them a hassle-free choice for various industries.

Safety Mechanisms

Safety, being paramount, is an integral feature of the Schrader valve. With built-in safety mechanisms, they ensure that over-inflation risks are minimized. Their design reduces the chances of accidental depressions, thereby providing a safe experience for users.

In essence, these features make Schrader valves highly reliable, versatile, and user-friendly, solidifying their position as a standard choice in multiple industries.

Contemporary Adaptations and Innovations

As industries evolve, so do the requirements of their components. Schrader valves have seen a plethora of innovations catering to modern-day demands. Whether it’s the integration of sensors for pressure monitoring in automotive tires or the development of miniature versions for medical applications, Schrader valves continue to adapt and prove their relevance in today’s world.

Future of Schrader Valves

The Schrader valve has been a mainstay in various industries for well over a century, but as with any technology, its continued relevance depends on its adaptability to changing needs and advancements. Let’s consider the potential future of Schrader valves based on current trends and technological trajectories:

Integration with Advanced Technologies: As vehicles become more connected and digital, Schrader valves might further integrate with advanced sensing and communication technologies. The current integration of TPMS (Tire Pressure Monitoring Systems) in vehicles is a prime example. We might see more advanced sensors that not only detect pressure but also other tire health indicators.

Material Innovations: Future Schrader valves might employ advanced materials that are lighter, more durable, and environmentally friendly, catering to industries that prioritize weight-saving and sustainability.

Sealing Mechanisms: As material science progresses, the sealing mechanisms in Schrader valves might benefit from enhanced materials that offer better durability, resilience, and adaptability to a wider range of temperatures and pressures.

Specialized Designs: Based on industry-specific needs, we could see more specialized variants of Schrader valves. For example, in aerospace or deep-sea applications, the requirements differ significantly from automotive or bicycle uses.

Environmental Considerations: With increasing emphasis on sustainability and environmental considerations, there might be innovations to make Schrader valves more eco-friendly, from manufacturing to disposal.

Competing Technologies: As with any technology, there’s always the potential for newer, more efficient valve designs to emerge that could challenge the dominance of the Schrader valve. However, given the entrenched position of the Schrader valve in many industries, any new design would need to offer significant advantages.

Digital Evolution: In a world moving towards IoT (Internet of Things), Schrader valves might evolve to have embedded digital components allowing them to communicate real-time data to centralized systems, especially in industrial settings.

Standardization and Interoperability: As industries increasingly value systems that can interoperate and standardize, Schrader valves might further evolve to meet universally accepted standards, ensuring compatibility across diverse applications.

See more: Presta Valves

While the fundamental design of the Schrader valve might remain largely unchanged due to its proven efficacy, its features, materials, and integration with other technologies are likely to evolve. This adaptability will be crucial for its continued relevance in a fast-changing technological landscape.

Conclusion

In sum, Schrader valves, with their distinctive characteristics and versatile features, have solidified their position as an essential component in various applications. From their inception to their present-day innovations, they serve as a testament to engineering excellence and adaptability. As we look towards the future, there’s no doubt that Schrader valves will continue to play a pivotal role, meeting the ever-evolving demands of industries worldwide.